SUPERFINISHING

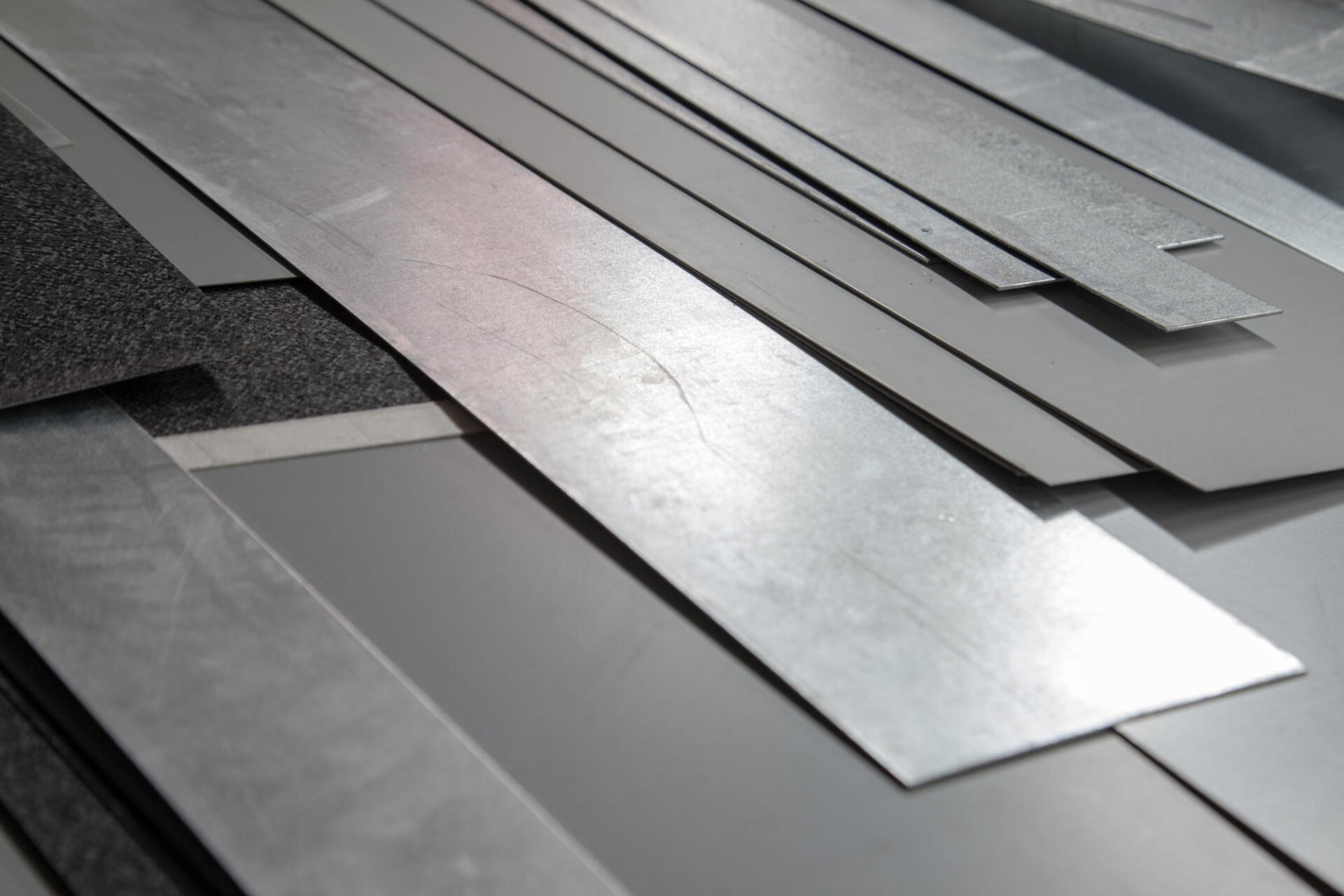

Sheet metal grinding

Sheet metal grinding, with the help of modern machines, is indispensable for professional processing and high-quality design of workpieces.

The purposes of grinding are extremely diverse. Depending on further processing, area of application and composition of the material, sheet metal grinding fulfills various tasks within its higher context.

As a market-leading manufacturer of grinding machines and grinding systems of all kinds, LOESER has been producing solutions for processing metals and numerous other materials for decades. Our constant pursuit of innovation produces state-of-the-art technology that brings numerous benefits in practice and revolutionizes the grinding machine market.

LOESER's modular machine concept enables tailor-made solutions for your company that nevertheless meet the quality of proven series production at the highest level in every respect.

Sheet metal grinding: Applications

An attractive surface finish is crucial for numerous products, as sheet metal parts are often found, for example, as cladding – clearly visible to the customer – on the exteriors of various devices.

A noble aesthetic, which can be achieved by LOESER's modular machine systems in time-efficient work steps, contributes significantly to the value and pleasant feel of a product.

Our technology offers excellent roughness values by using small-grain abrasives that are easy to change and ideally matched to our machines. In the area of sheet metal products with subsequent direct consumer contact, however, sheet metal grinding is by no means only about aesthetic factors, because the professional processing of workpieces also directly establishes the safety of a product and makes components usable without risk.

The deburring process mentioned here is carried out by a

two-step method used by LOESER. Material buildup, which is often residue after milling or punching a component, is removed by deburring according to your individual requirements and to the lowest tolerances, preparing the components for assembly or further processing. In coordination of specific tools and modular attachments, both edge rounding and surface finishing are fulfilled exactly according to specifications.

Precise sheet metal grinding also finds numerous applications beyond end devices with

high-quality surface finishes, because professionally ground components ensure that cables can pass through without damage and the function of devices is thus reliably protected in the background.

Challenges in sheet metal grinding

In view of the considerable range of applications in which LOESER grinding machines are used, sheet metal grinding is more a general term for a complex field of machining processes. This fact must be taken into account by contemporary and practical solutions.

On the one hand, this is due to the fact that the various industries place different demands on our machines, which are answered innovatively by our modular machine concept. On the other hand, the diverse materials that can be machined with our solutions require

high-performance machines with user-friendly features - ranging from high cutting performance to superfinishing with cross-ground structure.

LOESER provides the technological requirements and professional expertise

to equip market-leading companies in industries such as aerospace, medical technology or the food industry with individually configurable systems. Sheet metal grinding involves the machining of essential components in highly complex drive systems, such as piston rings, clutch plates and other flat parts.

The challenges to our equipment are mastered by reliable development work of our engineers. This is why we are able to realize grinding machines and coordinated systems that will continue to meet all requirements in the future and lead the way as an initiator for improved production processes.

Machines from LOESER: Revolution in sheet metal grinding

Our solutions in the field of sheet metal grinding are multifunctional and can be adapted at a low level to all the needs you encounter in your plant or company.

The modularity of our machines is emblematic of

customer-friendly technologies that focus on supporting your operations. In doing so, we combine technical know-how with practicality in a unique way.

In everyday work, this manifests itself in reduced space requirements, as several work steps can be carried out on the spot thanks to the various attachments. On the other hand, our innovative machine designs result in time and cost advantages, because adaptable removal rates with coarser or finer abrasives as well as almost tolerance-free surface finishes can be achieved in just a few steps with the same equipment.

LOESER offers the intelligent

way to revolutionize sheet metal grinding in your company. You can rely on references from a wide range of industries. Thanks to this wealth of experience and our successful commitment to grinding technology at the cutting edge, we are your ideal partner for customized solutions in series production.

Centerless cylindrical grinding

Loops - between peaks

Thanks to our modular system, we can supply series solutions that are precisely tailored to your application.

Centerless - stationary - roll grinding

Efficient grinding technology "made by LOESER". As with all of our systems, you benefit from our modular system. Customized solutions in series.

Superfinish Microfinish

With up to 3000 vibrations per minute, you can achieve surface textures that are precisely tailored to your application.

chrome plating

Maximum safety and process monitoring.

Flat deburring

With our systems you achieve exactly the edge rounding and surface quality you need. Taking into account all process parameters such as feed rate and required edge rounding, we configure your system with the help of our modular system to suit your requirements.