Nanofinish attachments

Your lathe can do more!

Nanofinish attachments

Loeser is well known as market & technology leader when it comes to Nanofinish attachments to be mounted on lathes. With these nanofinish attachments you can transform your regular lathe into a machine that creates superfinish / nanofinish / microfinish surfaces with ease.

With this process, you can create surface finishes that are measured in nanometers. That is why the technology is named nanofinish, but also microfinish or superfinish are used synonymously.

Herewith surface finishes of up to Ra 0,05 and even finer can be achieved.

Nanofinish technology is used for crankshafts, camshafts, steering rack bards, gear pump shafts, piston pins and many further applications.

How is the nanofinish done?

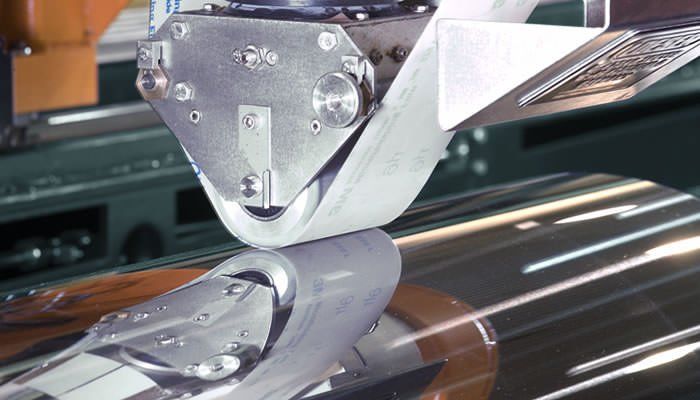

The surface treatment is carried out using a nanofinishing abrasive belt. These belt are 15 to 50 meter long and are available in different grit sizes. Typical grit sizes are from 0,1 to 100 µm. This nanofinish abrasive belt is unwound by a speed-regulated motor. The feed speed can be adjusted infinitely. The nanofinish abrasive runs over a pressure roller made of elastomer that oscillates along the workpiece axis. As continuously new abrasive is being used, the whole surface is finished absolutely homogenously and uniform.

It is the interplay of oscillation frequency, feed of the nanofinish device and the speed of the workpiece itself which are most important for the nanofinish result.

Of course the process is performed using either water, oil or emulsion.

Nanofinish

Loeser Nanofinish Aufsatzgeräte

Give us a call! We advise you on the technology of nanofinish!